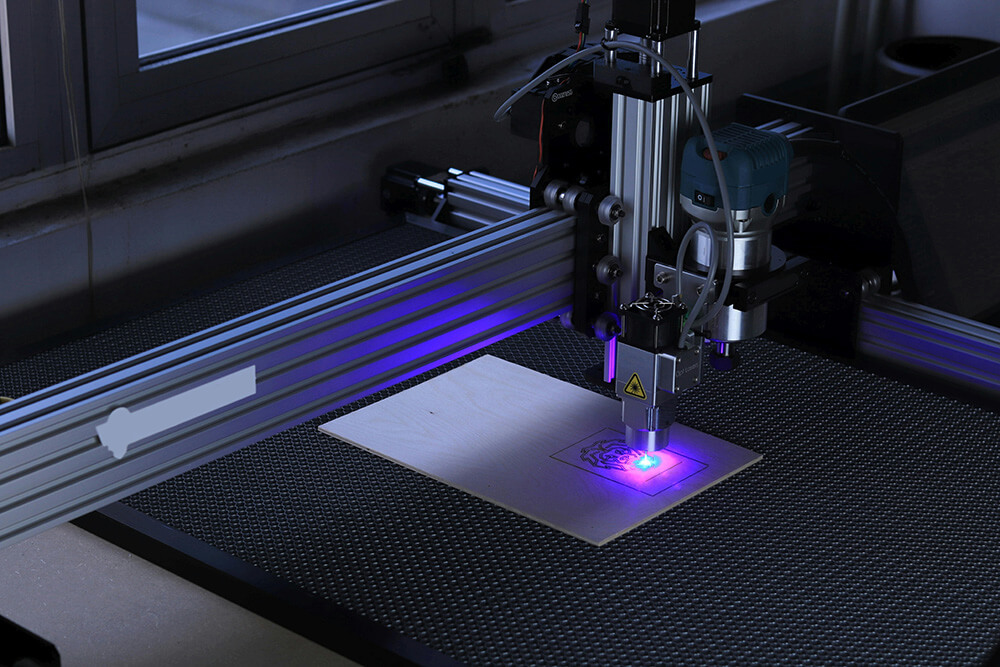

Laser cutting services are an invaluable asset for industrial manufacturers. Laser cutting offers a degree of precision, efficiency, and versatility that can significantly increase profitability in today’s manufacturing world.

With advanced laser cutting services, industrial manufacturers have the ability to create intricate and complex designs, enabling the production of highly detailed components that would otherwise be cost-prohibitive with conventional methods. The non-contact nature of laser cutting minimizes material distortion, reducing waste and enhancing cost-effectiveness.

W. M. Kelley Laser Cutting Capabilities

The W. M. Kelley team is highly experienced in the area of industrial laser cutting. Through the speed and automation capabilities of our laser cutting services, we’ve contributed to faster production cycles, enabling our customers to meet tight deadlines and scale their operations efficiently.

We pride ourselves on our ability to process a wide range of materials with precision and efficiency. Our laser cutting services are equipped to handle various materials, including carbon steel up to 1″ thick, aluminum up to 3/8″ thick, and stainless steel up to 1/2″ thick.

Whether the project demands intricate designs or large-scale projects, we meet specific project requirements with quality results.

Ready to Meet Custom Manufacturing Needs

Because our capabilities for laser cutting services are extensive and geared towards meeting specific needs, we are adept at working with custom designs or intricate cutting requirements.

Our production team is well-equipped to work from customer-supplied DXF files, ensuring precise execution of designs. If design assistance is required, our experienced design team can create the necessary laser files tailored to project specifications.

Note: Our capabilities extend to parts that are not larger than 158″ x 79.5″ and do not exceed the maximum thickness for the material. With these parameters in mind, we’re committed to delivering necessary solutions efficiently and accurately.

Forming, Finishing, and Assembly

Along with our advanced laser cutting capabilities, we are equipped with an extensive range of press brakes and punch and die configurations to accommodate various forming requirements.

With four brakes ranging from 75 to 350 tons, we can efficiently form parts up to 14 feet in length, ensuring precision and quality in every project.

Our facility features a state-of-the-art continuous flow powder coating system with impressive dimensions of 70 inches wide by 84 inches tall throughput. This system, coupled with our spray enamel, epoxy, and mastic capabilities, enables us to provide superior finishing solutions tailored to your specific preferences.

Whether you require standard industrial colors or a custom match, our extensive stock and color matching capabilities ensure your satisfaction.

W. M. Kelley Offers a One-Stop Source

In addition to offering laser cutting services, W. M. Kelley offers a full suite of capabilities, for a one-stop solution for clients seeking a turnkey fabrication process. Our capabilities include:

- Laser Cutting

- Sawing

- Punching

- Drilling

- Machining

- Rolling

As a team we offer customers more than facility and machinery. With over 50 years of assembly and testing experience, our team is adept at handling various material handling equipment. We ensure the highest standards of quality and functionality, providing you with reliable solutions that meet your specifications.

Feel free to reach out to us with any further inquiries or to discuss your specific project requirements in more detail.

Tell us about your project.

When it comes to metal fabrication, you need a partner you can trust. Contact W. M. Kelley today to

discuss your project, request a quote, or simply learn more about how our expertise can benefit you.

We look forward to the opportunity to collaborate with you on your next metal fabrication endeavor.