Lauyans EPS has a history of innovation, years of experience, technical abilities, skilled people and clear understanding of how to meet our customers’ needs.

We have delivered a multitude of material handling solutions that are successfully serving customers in a broad and diverse range of industries.

Our team supplies quality engineered material handling solutions, including conveyor systems that meet the unique needs of the specific industry and process.

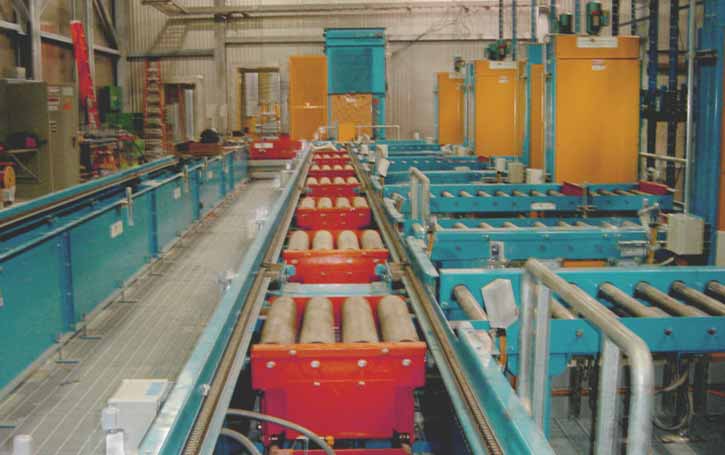

Dry Goods Distribution Center

System: Ten automated pallet receiving cells designed to expedite the truck unloading process. Each cell can automatically weigh, size and re-square incoming pallet loads before they are introduced to this automated storage and retrieval system.

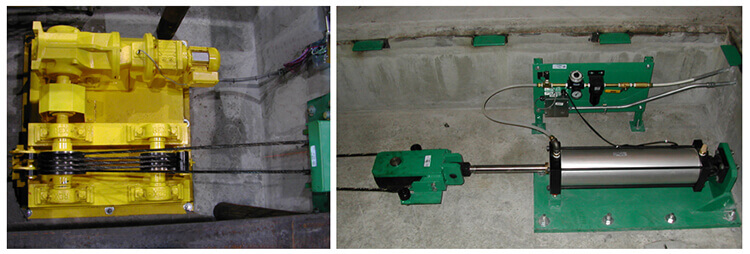

Automotive Manufacturing Storage & Retrieval Machines

System: Three automatic delivery transfers were designed and integrated into an existing live roll conveyor system; to allow interface with new storage and retrieval machines.

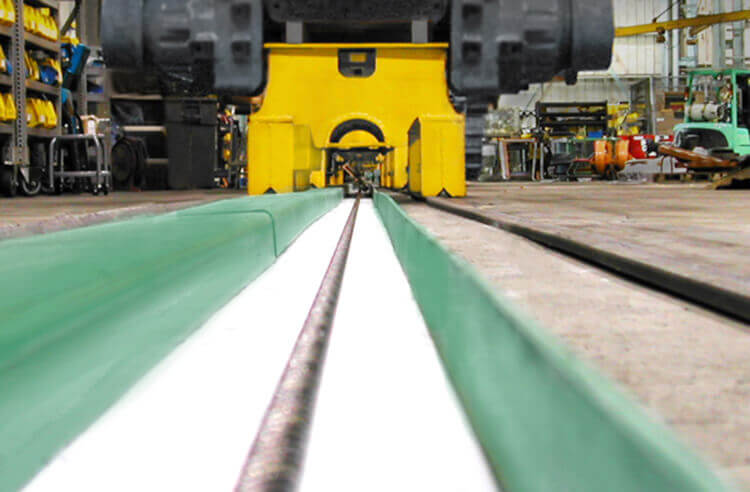

Excavation Equipment Manufacturing

System: An existing final assembly line was retrofitted with a Powered Tow Line Conveyor. The new system required pits for the drive and take-up; with the entire intermediate track being installed above the finished floor.

Chemical Processing

System: A fully automated packaging system was integrated to erect cases, place them on pallets, automatically insert liners, and deliver the empty cases to one of three auto filling positions. After filling, cases are queued for pick up by fork lifts which deliver to the warehouse.

Poultry Processing

System: A fully automated two-level system integrated in a refrigerated warehouse. The system interfaces with an Automated Storage & Retrieval System on one level; and delivers loads to ergonomic packing stations for processing and then delivery to shipping.

Tell us about your project.

Our goal is to not only provide the equipment you need, but to help you develop a comprehensive solution.

In designing your custom conveyor system solution, we focus on your needs, your business, and your budget.