Heavy Duty Dumper

For more than 25 years, Lauyans & Co. has served a customer in the Bio-Medical Waste business. Some years ago, this customer presented us with a request. They wanted dumpers that lasted longer in the harsh environment of their operations. A previous supplier had provided dumpers to handle large bins. The units did not survive long in the customer’s environment. Our customer was tired of having to rebuild and replace these units.

These environmental issues had to be addressed:

- Bio-Medical Waste (typically red-bag waste from hospitals and medical offices) is brought in and sterilized

- Processing areas are washed down frequently

- The waste tends to stick inside containers. Operators have to cycle the dumpers multiple times to get the waste to fall out

- Waste can contain high levels of uric acid which is very corrosive

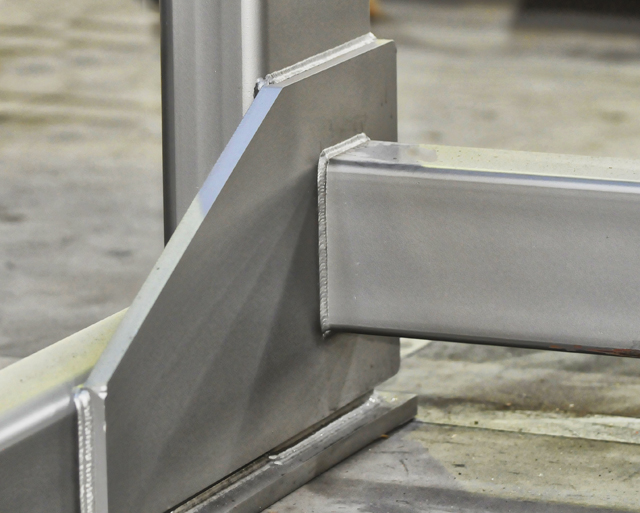

Lauyans designed the new dumpers to have a longer life and require less maintenance. The design includes:

- An extremely Heavy Duty design. The pivot shaft, for example, is 4 ½” in diameter

- Units are painted with “STEEL-IT” Polyurethane Coating System that features a unique stainless steel leafing pigment to resist corrosion

- Heavy fork construction

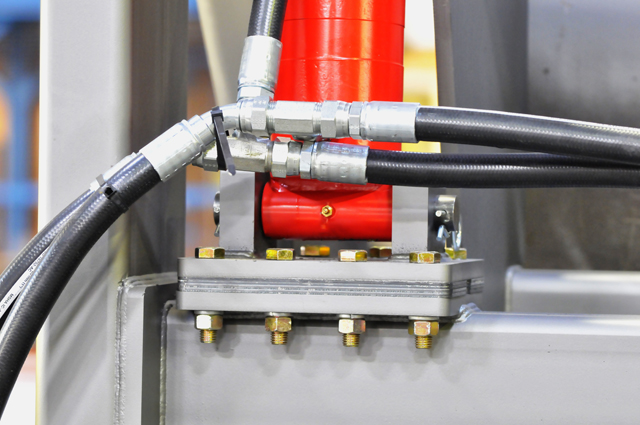

- A heavy duty hydraulic package allows for faster cycle times

Our customer has been extremely satisfied with our equipment. The dumper pictured here is a new design that a higher lifting requirement. It replaced a 2-stage dumper that provides a simpler design with fewer components, a shorter cycle time and increased load rating of bins holding up to 4400 pounds. It incorporates a refined 2-speed hydraulic controls package that reduces cycle time and provides a more controlled descent of the empty bins.

In addition to bin dumpers, Lauyans also provides a variety of material handling equipment to this customer. In the 25+ years that Lauyans has worked with this customer, we’ve requested feedback and revised designs accordingly. Improvements such as stainless steel support feet & motor shrouds and Steel-It paint in highly corrosive areas have increased equipment life and reduced downtime.

We are still listening to our customer’s needs, adapting our designs to satisfy the demands driven by the harsh environment and supporting continuous improvement in operations.