Heavy-Duty Conveyors: Proving Our Claim

If you go to Lauyans & Company’s website page for Custom Conveyor Solutions, we make a claim you can take to heart, “If your process requires moving heavy, unique-sized or hard to handle loads, we can help.” We’re very serious about that commitment. Read on.

Lauyans & Company’s customer manufactures wind turbine masts. You can imagine the size and strength required to support a wind turbine safely for years under all weather conditions.

Here’s how the process works. The masts are constructed in multiple sections. Each section must process through several stations.

The manufacturer was using overhead cranes to move the mast sections from station to station. Safety was a major concern. Time was as well. How could Lauyans & Company help?

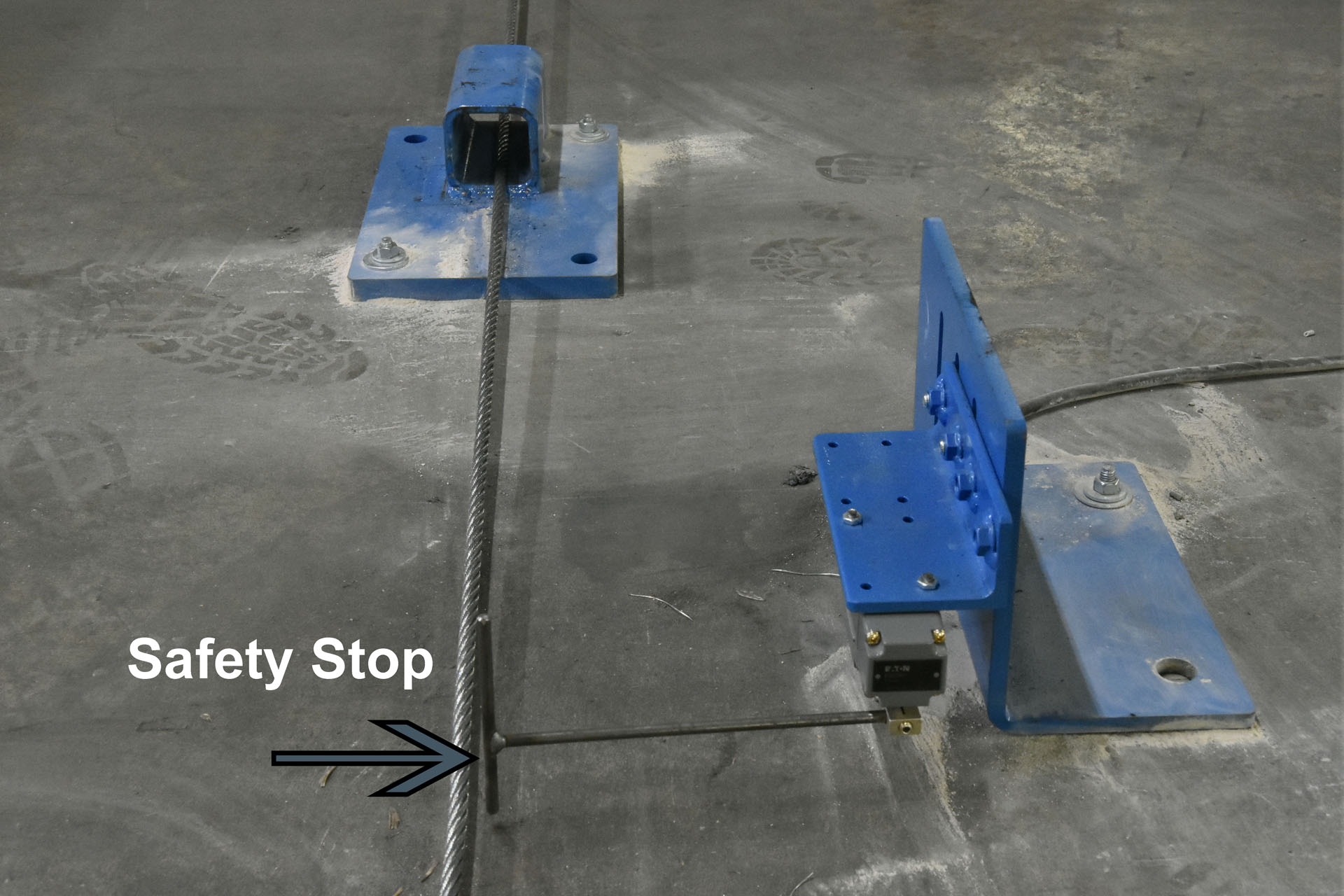

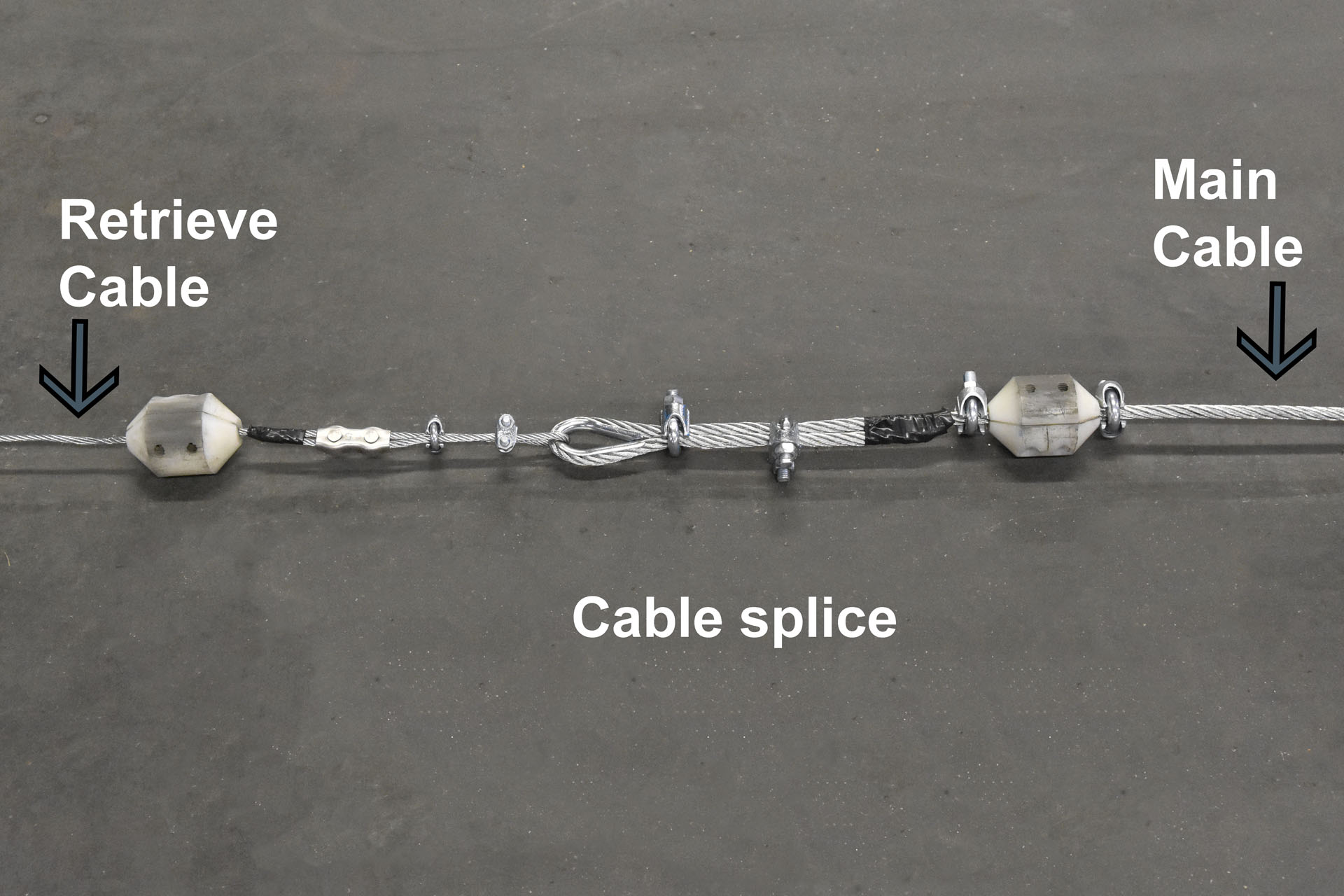

Lauyans & Company’s design utilizes tow-line conveyors, one for each of 3 lines. The mast sections are placed on large carts that carry the sections from station to station. The carts allow the mast sections to rotate. Each cart can be attached to the tow-line with a clamp. Several carts are pulled along at a time. When a mast is complete and the cart carrying it reaches the end, it is removed from the line. The tow-line is then pulled back to the point where the other carts are re-attached, and a new cart can be added at the start of the line.

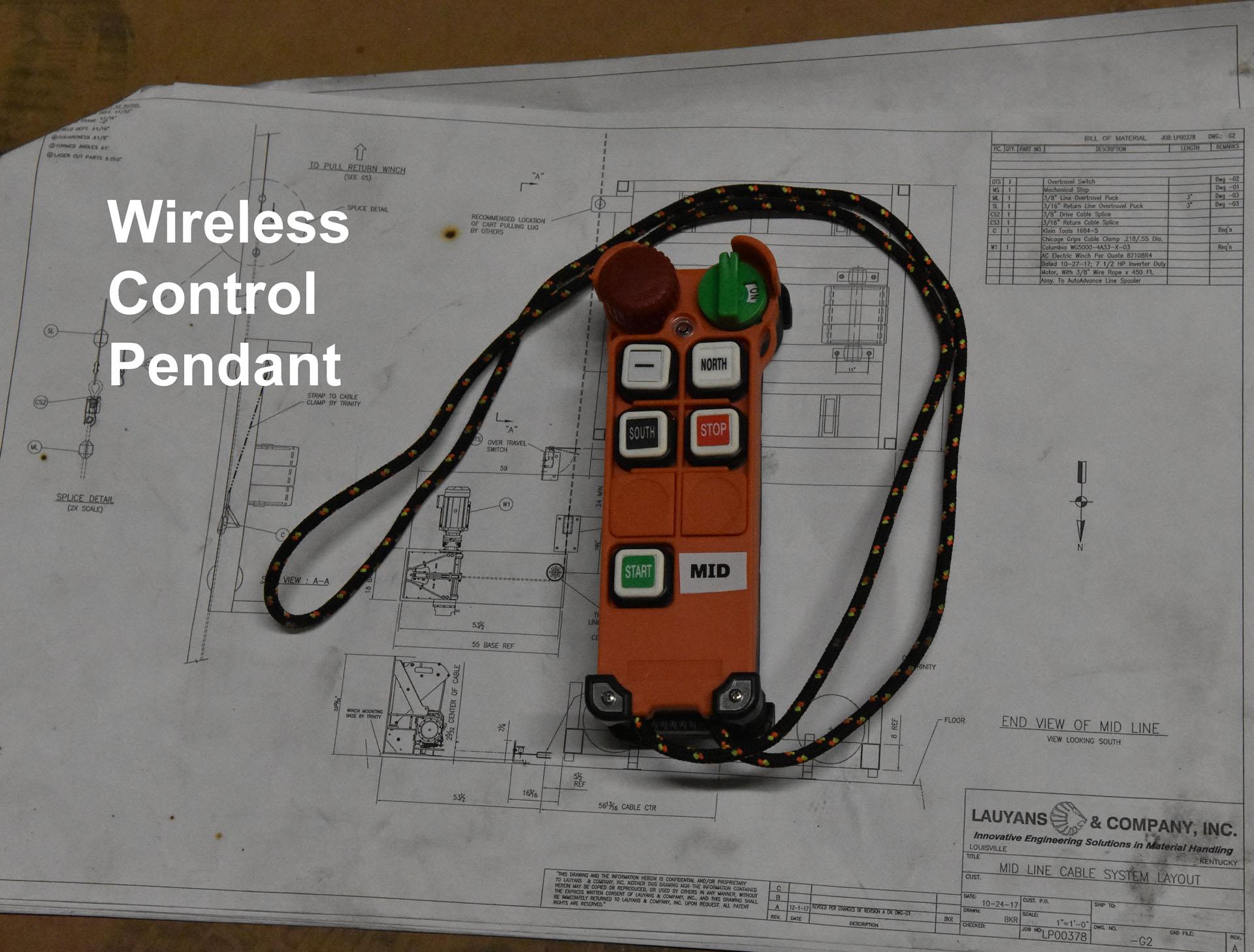

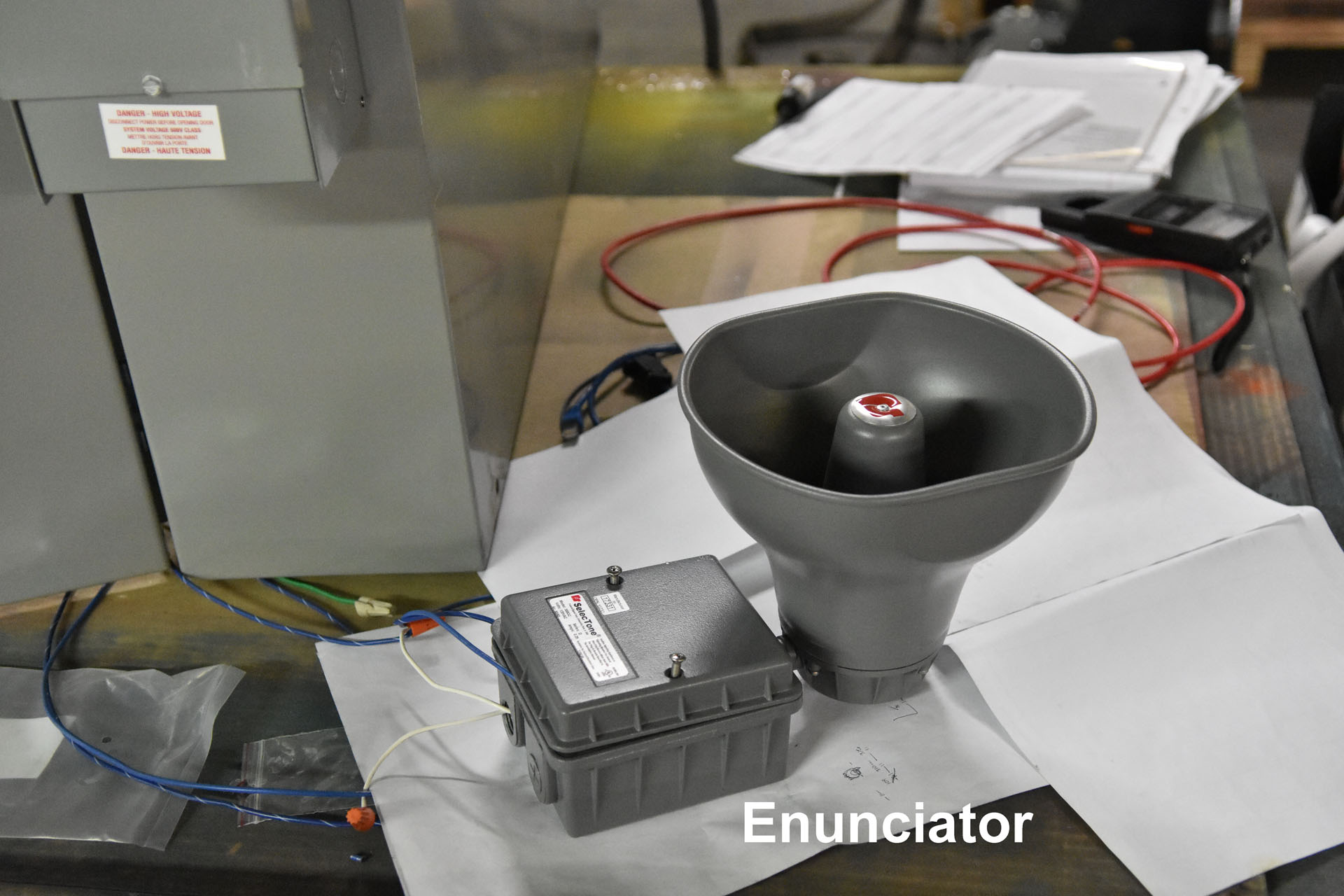

One winch on each line pulls the loaded carts. Another winch at the opposite end, 356 feet away, retrieves the cable. An operator operates both winches utilizing a wireless pendant control. The wireless feature avoids having to run electrical wire between the winches. Anytime the line moves, an enunciator at the control panel issues a warning.

If you have a process that “requires moving heavy, unique-sized or hard to handle loads, we can help.” Try us on that!