Perfect Pick and Place Automation with a Conveyor Upgrade

High speed and accuracy make robotic technology an ideal concept for pick and place applications in a wide range of industries. Tremendous gains in productivity are realized through the application of pick and place robotic technology. More importantly, pick and place robots eliminate the risk of fatigue and injury human labor is subjected to in these types of applications. Employees can be better utilized in positions that are less redundant and less ergonomically problematic.

Realizing the full potential benefit of robotic pick and place technology requires a material handling system that can match the speed of the robot, to keep work flowing and prevent problems from occurring. A custom conveying system engineered for integration within a robotic pick and place process is the best way to assure that the full potential of the robotic system will be realized.

Applications that are especially well-suited for pick and place robotics with integrated conveyor systems can include:

- High Speed Assembly – Robots pick parts from a feeding conveyor and transform them into assemblies, which are carried by an outgoing conveyor.

- Inspection and Quality Control – Precision robotic technology is used to visually inspect components and pick out deflects, as the parts pass on a high speed conveyor.

- Rapid Packaging – Items are dispersed on a conveyor moving at high speed and robotic visual technology is used to transfer the product into packaging containers.

- High Speed Sorting – Visual robotic technology rapidly picks and separates different types of components passing on a high speed conveyor.

Matching the capability of robotic technology is no small order. In robotic pick and place operations, through-put can be as high as 200 pieces per minute. Visual robotic technology can identify more than 100 items per second. Only a conveyor system engineered to match this capability will meet the challenge.

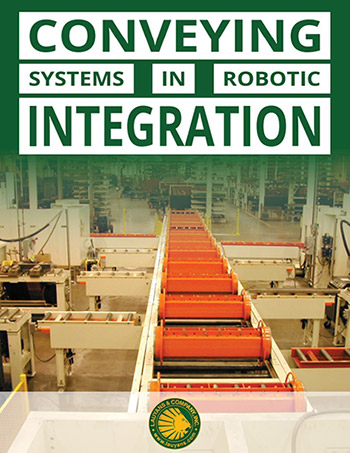

Download Our Guide to Conveying Systems in Robotic Integration

Take a closer look at the beneficial role of automated conveying systems in various robotic applications.