Special Applications – Transporting 2,000°F. Axle Blanks

There are a number of companies that produce standard conveyor by the mile. Products handled in these projects are usually of similar size, shape and weight. The environment is easily accessible; typically not too warm nor too cold. No environmental issues such as bacteria, radiation, dripping fluids or corrosives.

Lauyans & Company’s ability to provide material handling products for extremely complex and demanding situations set us apart from our competition. These situations can include temperature extremes of minus 20°F to a positive 2,000°F. Other situations require solutions to handle products as diverse as biomedical and nuclear waste or trays of frozen chicken. If products or environments are difficult to work with, we’ve probably already handled them.

Here is an example that shows how we’ve handled a really tough situation for customers involving high temperature.

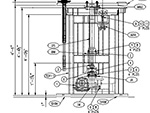

Situation – Transport 2,000°F. axle blanks from header to robotic machining

Design / manufacturing requirements:

- Axle blanks were heated to +2,000°F.

- Conveyor had to function reliably over a wide temperature window of approximately 35°F. (off-shift) and +2,000°F. (during production)

- Conveyor was designed not to deform during cooling, heating or in production

- Special fasteners required to prevent loosening during heating and cooling

- Special coatings required to protect surfaces of conveyor from jamming, rusting, etc.

- High-tolerance placing at interface with robotic machining station(s)

Today, Lauyans & Company, Inc. is known throughout the material handling industry for its strength in providing innovative solutions in material handling. We use creative engineering along with advanced product technology to create solutions that solve industry’s needs. We probably have already tackled a project similar to yours!