The legend continues with a deep respect for the traditions…

Kentucky bourbon is legendary. Bourbon is associated with bluegrass, limestone, and horses. Bourbon is

also associated with history. Most of the well-known bourbon brands hark back to distilleries that have

been in business since the 1800s. Take a walk through a distillery. You’ll see old brick structures that are

sometimes almost 200 years old. There is a tremendous sense of history and a value for tradition in the

bourbon industry. Lauyan’s EPS understands that. Lauyan’s EPS knows how to work with any constraints

involved in historic industries.

When Lauyan’s Engineered Product Solutions works with our customers that distill and age bourbon

whiskey, the age of the structures makes what we do for them very special. The age of a structure and

the existing conveyors played a part in this project.

The issue here for our customer? Streamlining the receiving and inspection of new, white oak barrels for

the aging of Kentucky bourbon.

The challenge for Lauyan’s EPS? To seamlessly mesh the new equipment and the controls with a building

and conveyors that have been in place for scores of years. Maybe since the 1800’s when the same

operation was done by hand.

Our customer brings in new, 120-pound white oak barrels by truck load. The inside of each barrel has

been charred at the cooperage. The barrels are ready to be filled with Kentucky bourbon whiskey so that

the legend continues.

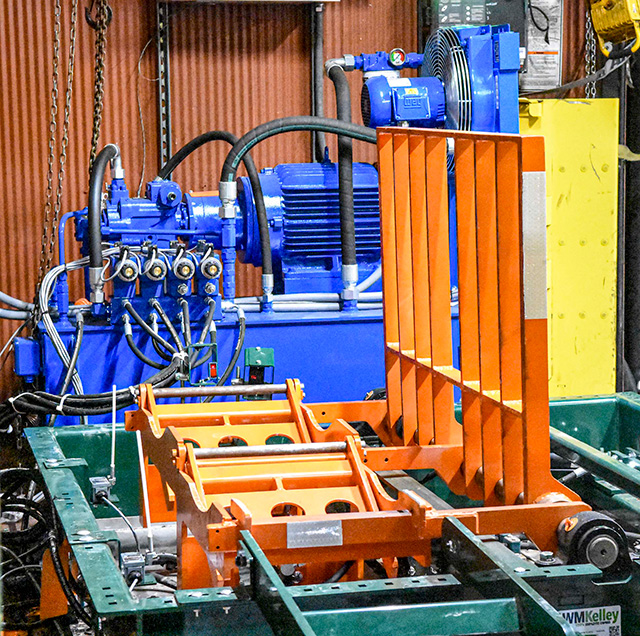

At the dock, a forklift pulls two barrels at a time out of the trailer and puts them on a platform. As the

forklift backs away, the platform rotates to “down end” the barrels onto their sides. One at a time, the

barrels are released and roll onto the mainline conveyor. The barrels are rolled on the conveyor so they

can be inspected visually for defects. The inspector accepts or rejects each barrel.

A flawed barrel is pushed off the line to a reject area.

An accepted barrel continues along the mainline conveyor until it reaches a queue with an open spot. It

is conveyed into the queue to await filling.

Once filled, the barrels are stored in a rick house for aging. The aging process can take as long as the

distillery needs for a particular brand of bourbon. Here is a fun fact; straight bourbon whiskey must be

aged for a minimum of two years, and bottled-in-bond must be aged for at least four years.

The legend continues.

Does your company need to match cutting edge material handling equipment with historically

significant infrastructure? Does your company have to interface with your client’s existing equipment,

from a bygone era, that still works as it was originally intended?

Lauyan’s Engineering Product Solutions has the knowledge and experience to handle unusual

challenges. We’d love to discuss your situation with you. Please call us.