Tote Stacker ǀ Destacker Saves Space, Reduces Time for Fashion Apparel Industry

Lauyans & Company manufactures Tote Stacker ǀ Destackers for a wide variety of uses in manufacturing, fulfillment and distribution. Here is a recent example.

We are a designer and manufacturer for a multinational integrator who specializes in the areas of distribution, e-commerce and 3PL. With offices in many countries and a strong background servicing the retail industry, this integrator is the preferred solutions provider for apparel manufacturers, retailers and distributors.

The integrator is a solutions provider to a company in the fashion apparel industry for their distribution facilities. The end user puts an emphasis on fashion and quality at the best price in a sustainable way. To maintain that emphasis, they needed a device to collect, store and dispense totes for the order fulfillment part of their operation.

The biggest issue faced by the end user was a problem of space and time. Too many empty totes were sitting around their facility. Empty totes took up a lot of floor space. Another problem was it took too long to gather the totes and re-insert them into the distribution system. They wanted the ability to collect and store the accumulated totes in a single area. An important part of the solution would be a ready buffer for their fulfillment operations to handle surges.

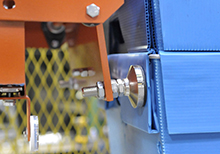

Lauyans & Company provided the solution. We designed and built a Tote Stacker ǀ Destacker with controls to work in conjunction with two belt conveyors and the company’s ERP to handle the accumulation and dispensing of empty totes at the necessary rate. The resulting Tote Stacker ǀ Destacker is able to maintain a steady flow of totes to the fulfillment operation without being a bottleneck or damaging the totes.

On one side of the Tote Stacker ǀ Destacker, multiple stacks of 14 totes are accumulated and staged on a belt conveyor. After Lauyans & Company’s Tote Stacker ǀ Destacker presents one stack, a single tote at a time, onto a belt conveyor to the fulfillment process, a fresh stack of totes is moved into the Tote Stacker ǀ Destacker from the accumulation buffer. The Tote Stacker ǀ Destacker is flexible and can handle stacks of different quantities. This allows it to stop dispensing totes at any point in the operation and collect empty totes coming back from the distribution area.

Empty totes are returned to the Tote Stacker ǀ Destacker where they are stacked and restored to the accumulation / buffer conveyor.

Click below to see a video of this machine as it functions during the factory run-off at Lauyans & Company’s plant.