Efficiency for the Automotive Industry

Lauyans & Company’s customer works with major automotive manufacturers. They provide carpeting and pads using recycled materials. The product for this project is the insulation padding to reduce noise and insulate the passenger compartment.

First, the material is pressed into shape to fit the floor boards of an automobile. A water jet is used to cut holes in the pads. The completed pads are stacked 12 to a container or “crate.” The full crate is removed from the station and shipped to the assembly plant.

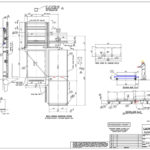

Lauyans & Company created a system that will queue empty crates on the in-bound and full crates on the out-bound sections of the station. An operator push button station is provided, to signal that a container is completed and ready to exit. A call button is also provided to deliver a new empty crate to the system operator.